Research Project “HYDROVIO”

Development of reversible pumps / hydroturbines

with optimized hydrodynamic and environmental design for high energy efficiency

and safe fish passage (HYDROVIO)

Official project website: www.hydrovio.gr

The research project “HYDROVIO” is

realized by the Laboratory of

Hydrodynamic Turbomachines (LHT) of the NTUA and the manufacturing company DRAKOS

– POLEMIS PUMPS, and concerns the study, optimal design

and laboratory validation of reversible pumps-turbines of special hydrodynamic

design to allow for safer fish passage to both directions, while maintaining a

high degree of energy efficiency.

These

machines can cover a multitude of applications, both in the field of

hydroelectric projects and energy storage units with pumped storage, as well as

in the fields of aquaculture, drying up of water areas and management of water

reserves.

Funding

The

"HYDROBIO" Project was implemented as part of the

RESEARCH-CREATE-INNOVATE Action and was co-financed by the European Regional

Development Fund (ERDF) of the European Union and by National Resources,

through the Operational Program Competitiveness, Entrepreneurship and

Innovation (project code:T1EDK-01334)

Main research objectives

1. Investigation of the international

market and determination of the design and operation region (hydraulic head and

discharge rate) of pumps and reversible machines ‘friendly’ to the fish fauna,

which is of commercial interest.

2. Creation of an innovative methodology

for the assessment and quantification through appropriate indicators of the

degree of ‘fish friendliness’ of a hydraulic turbomachine (pump, hydroturbine or reversible machine).

3. Development and implementation of an

integrated computational methodology for optimal, customized design of

reversible hydrodynamic machines, with two competing objectives: Maximizing

efficiency and minimizing impact on fish fauna.

4. Creation of an innovative system for

reliable diagnosis of cavitation in hydrodynamic machines, with easy adaptation

and portability.

5. Development and implementation of a

telemetry system for the online monitoring of the operation of large installed

pumps and reversible hydraulic turbomachines.

6. Publication and promotion in the

international markets of the new products, and the capability of the Company

for specialized research and development of innovation.

7. Strengthening through the cooperation

with the LHT-NTUA of the research department of the Company in

the area of hydraulic turbomachines design with

computational methods, and improvement of its infrastructure for testing and

evaluation of new products.

8. Expansion and reinforcement of the

research team of the LHT, and further enhance of its potential for development

of new innovative tools and methods, at the forefront of the international

scientific and technological research.

Project Methodology

The research

project “HYDROVIO” includes 7 Work Packages, and its duration was four years. Its

implementation is based on modern computer tools and software, on the advanced

and well-equipped laboratory infrastructures of the participants and also on new innovative methodologies and techniques that

are developed in the framework of the project.

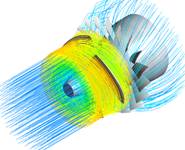

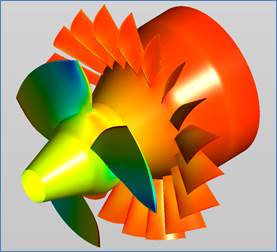

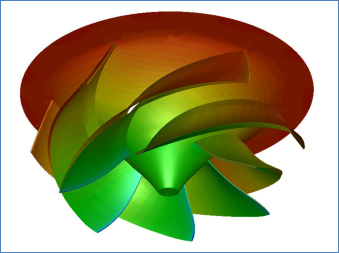

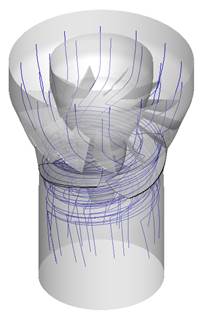

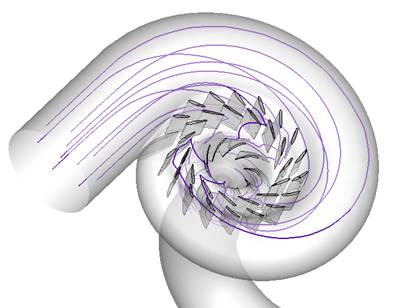

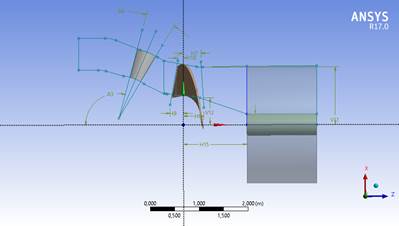

The first

key component of the proposed research includes the simulation and numerical

solution of Reynolds-Averaged Navier-Stokes fluid mechanics equations (RANS) in

the complex geometries of reversible mixed or axial flow hydraulic

turbomachines. To this aim, commercial computational fluid dynamics software is

used, in order to simulate at first the flow in the

runner / impeller (blade-to-blade), and then in the entire geometry of the

machines, including the inlet-outlet sections and the guide vanes.

The geometry

of the runner/impeller and of the rest components of the machine is introduced

in a parametric way, with techniques that are developed within the Project, so

that a wide range of different geometries can be produced using a relatively

small number of design variables. This parametric design allows for the

investigation of the effect of the various design parameters on the operational

behavior and performance of the reversible turbomachines, and then the

numerical optimization of its design, using relevant software.

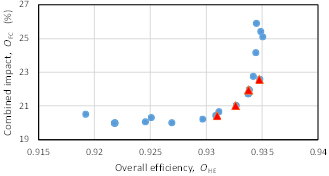

Two design

objectives are set: Maximization of the energy efficiency of the reversible

turbomachines and minimization of the possibility of injury or mortality of the

fish fauna that passes through them. These two goals may be competitive, and

hence, the multiparametric optimization procedure produces a set of optimal

solutions, the so-called Pareto front, on which a manufacturer will be able to

select a specific machine design, depending on the conditions and requirements

of each application.

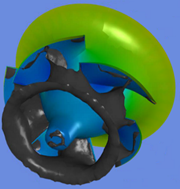

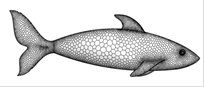

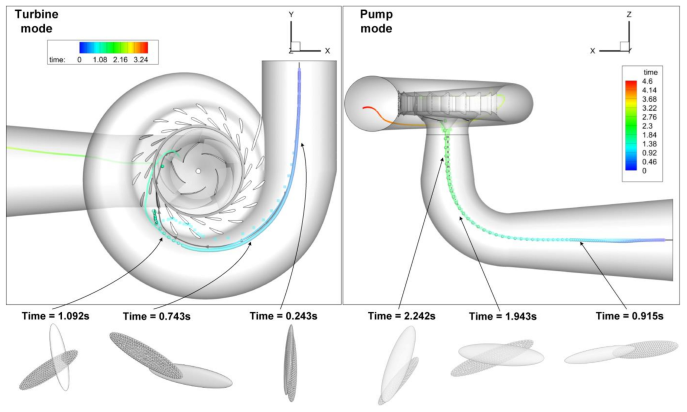

At this

point there is a need to quantify the degree of 'fish-friendliness' of a

hydraulic turbomachine, so that it can be set as an optimization target (cost

function). For this purpose, a new innovative methodology is developed,

according to which the motion of an object in the shape of a fish and with

variable dimensions can be numerically simulated, as it passes through the

machine. The hydrodynamic forces and pressures that are exerted on the

object-fluid interface (normal and shear stresses) are being recorded during

its trajectory, while at the same time they determine its motion in the flow

field at all degrees of freedom, as well as its possible impingement on the

inner solid surfaces of the machine.

Then, in order to certify the complete methodology of the optimal

customized design of a pump / turbine, the Company D-P Pumps studied and

manufactured on its premises two such models of reversible hydroturbines,

suitably selected from the computationally obtained optimum design results. Then,

the models are installed in the test rigs of D-P and LHT laboratories, and

their characteristic operating curves are measured with modern equipment.

Especially

for the mechanism of cavitation, an innovative detection methodology that was

being studied in LHT is completed and applied, and it is combined with a

telemetry technique, so that the whole device is portable and can be easily

installed in a real pump or hydroturbine in

operation.

Project Results:

The progress

and implementation of the Project and all its Work Packages were made in

accordance with the technical descriptions and objectives, as originally set

and described in the Technical Appendix. All Work Packages completed

successfully.

The

collaboration of the Laboratory of Hydrodynamic Machines NTUA (LHT/NTUA) and

the research department of the Company, DRAKOS-POLEMIS PUMPS was excellent, and

the successful implementation of the Project enabled both NTUA and the Company

to expand and strengthen their research groups, with further development of

their capabilities to create new innovative tools and methods, at the cutting

edge of international scientific and technological research.

Specifically,

from the beginning of the Project to its completion, the following were carried

out:

The

international market was investigated and the area of design and operation

(hydraulic head and nominal flow) of 'fish-friendly' pumps and reversible

engines identified, for which there is commercial interest. Also, all the basic

tasks & preparatory actions for the implementation of the Project were

completed, regarding the selection of machines to be investigated, the

literature review in order to identify the necessary

design criteria for hydrodynamic machines with a low fish mortality index, and

the investigation of the application range of pumps, hydro turbines and fish

friendly reversible machines.

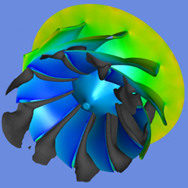

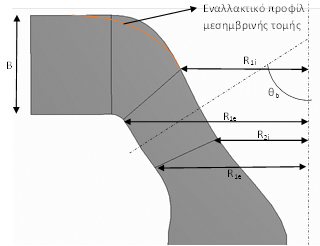

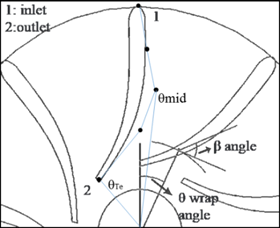

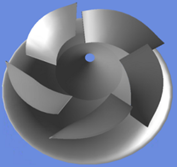

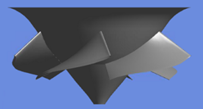

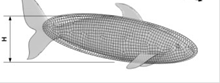

A new

methodology was developed for the parametric design of the rotor/impeller and

the other parts (inlet, outlet, casing, etc.) of two different types of

reversible hydro-turbine pumps (axial and mixed flow), with the introduction of

a number of variable parameters to describe the geometry of the various parts,

so that modifications of the original design can be produced in an automated

way and in the desired range. Next, the details of the final selection and

generation of the computational domain and the numerical mesh, as well as the

computational data, boundary conditions and numerical simulation procedure,

were determined. Finally, the computational platform was configured, using

appropriate computational fluid dynamics software, to solve the flow in these

two types of machines, both for pumping and turbine producing operation.

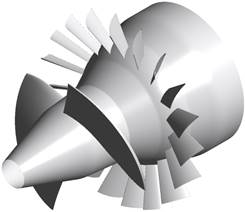

Specific

reversible hydrodynamic machines (pumps-hydroturbines)

of different type and operating area were chosen for study: one axial flow

machine, with low hydraulic head and two mixed flow, higher head machines

(Francis and Deriaz). The main design parameters of

these three machines were thoroughly investigated, with multiple numerical

solutions of the flow, in order to draw conclusions on

the effect of the various hydrodynamic design variables on their hydraulic

performance and the potential effects on passing fish fauna, for both pump and hydroturbine operation. Appropriate correlations and

indexes from the literature for the effect of the rate of change of static

pressure, the magnitude of shear stresses and the probability of impingement on

solid boundaries, along a representative number of flow lines, were used to

assess the effects on fish fauna.

|

|

|

|

|

|

|

|

|

|

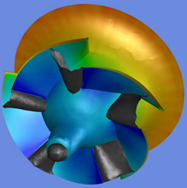

Then, after

parametric investigation identified the most critical design parameters of the

two machines and determined the desired range of their values, a numerical

optimization of the design of the reversible axial flow machine and the Deriaz mixed flow machine was carried out, which showed

better results against the Francis machine, regarding the effects on passing

fish fauna. The optimization has two parallel objectives: maximizing the degree

of energy efficiency of a complete pumping-production cycle and minimizing the

impact on passing fish. These effects were defined based on the various

relevant indicators and their combinations, and thus various optimization

procedures were implemented for each machine. Applying the Design of

Experiments method, multiple numerical solutions of the flow in the two

machines for the pumping and production operations were carried out, in order to finally obtain sets of optimal solutions (Pareto

fronts), on which the manufacturer can choose a specific machine, depending on

the conditions and requirements of each specific application (e.g. operating

program, species/size of fish, etc.).

In order to certify the integrated methodology of optimal

customized design of the new machines, studies were carried out concerning the

implementation of their scale models and their testing in the laboratory. The

design was carried out in a two-dimensional and three-dimensional environment.

The machines were studied in terms of the materials of the parts, their

strength/stress, the sealing of the structures and their assembly. All the

required construction engineering plans for the production process were

completed, and the selection of materials and the determination of casting

types were carried out, based on the choice of casting technique. International

technical standards were followed for the engineering studies and the adoption

of design methodology, such as tolerances of construction plans and assemblies.

Finally, all individual stages of the production process were analyzed and the construction of the models of the two new

machines was completed by the Company.

|

|

|

|

|

|

|

|

|

|

The new

machines were then delivered to carry out their laboratory evaluations. The

laboratory test rigs of the Company and the NTUA Hydrodynamic Machines

Laboratory were prepared with the necessary modifications, additions

and configurations to the hydraulic circuits, in order to connect the new

machines. Two different test circuits were set up in the LHT/NTUA, one for the

axial flow model, which requires relatively large flow rates and small heads,

and one for the mixed flow model, with smaller flow rates and pipe diameters.

Also, the required measuring equipment was prepared and calibrated, with the

control and calibration of the measuring instruments and their installation in

the test rigs, as well as the software for taking and recording the measurements.

The two new models of reversible machines were finally successfully installed

in the laboratories by the staff of LHT and the Company.

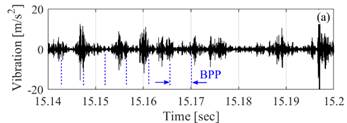

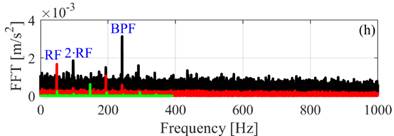

An important

goal also achieved was the creation of an innovative hardware-software system

for the reliable detection/diagnosis of cavitation occurrence in hydrodynamic

machines, with easy adaptation and portability. The Spectral Kurtosis method

was applied, with the aim of constructing special filters, which can isolate

the characteristics of the phenomenon from the total measured signal received

by special sensors (accelerometers), which are placed in appropriate points on

the machines' shell. This new methodology, which is an international

innovation, was developed in laboratory pumps and successfully tested on the

mixed flow model within the framework of the Project.

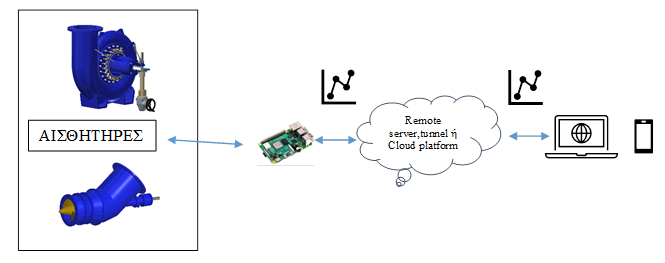

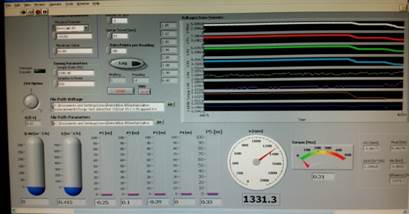

At the same

time, with the use of modern technology based on IoT (Internet of Things), the

Company developed and implemented a telemetry system to monitor the operation

of machine models, but also potentially large installed pumps and reversible

pumps-hydroturbines. The system includes custom

sensors, combined with the Raspberry Pi microprocessor and PI tunnel web

portal, and it is flexible and scalable, even for remote control of the

machines. The system was connected to the internet and its capability of remote

monitoring of the operation of the laboratory models was confirmed.

Another

important objective of the Project was the development of a methodology for the

assessment and quantification through appropriate indicators of the degree of

'friendliness' of a hydrodynamic machine (pump, hydro turbine or reversible),

in terms of the fish fauna passing through the machine, which is applicable to

any hydrodynamic reaction machine. The new, innovative methodology developed in

the framework of the Project can simulate with satisfactory accuracy and low

computational cost the 6 degrees of freedom motion of objects within complex

flow fields. It was successfully applied to the monitoring and statistical

analysis of fish trajectories through reversible pump-hydro turbines, such as

those developed in this Project, confirming their improved environmental

design. In addition to kinematics, it is possible to record data to extract

indicators of fish injury, such as pressure, shear stresses and impacts on

solid surfaces, allowing the definition of a proposed general index of

'friendliness' of hydrodynamic machines.

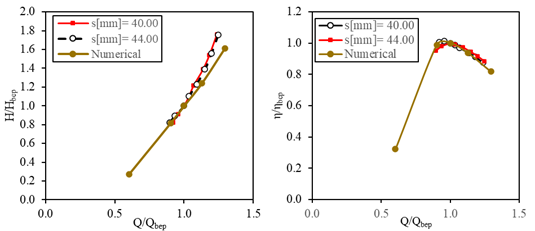

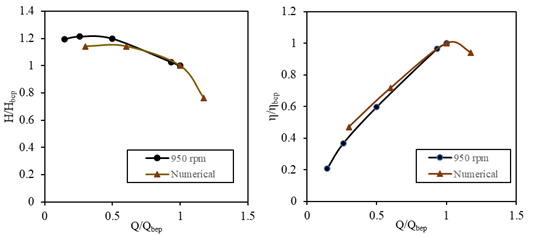

In order to certify the

new methodology for customized optimal design of a pump/hydroturbine,

the models of the two new machines were installed in the laboratory setups of

the LHT/NTUA and the Company, and the specifications of testing procedures were

determined. The machines were then operated as pumps and as hydroturbines,

and series of measurements were taken in order to obtain the respective characteristic curves over

a range of their operation. It was found that the performance of the models in

both modes of operation is smooth, without dynamic phenomena, and in agreement

with their theoretical and numerical design specifications.

The sources

of errors during the laboratory measurements were analyzed and the uncertainty

of the measured quantities was calculated, and found

to be adequately low. Finally, the repeatability of the measurements was

checked and confirmed to be within the uncertainty limits of the tests.

As a final

evaluation of the two new machines, the characteristic curves of the laboratory

models were compared with the corresponding curves obtained from the numerical

simulation, both for hydroturbine operation and for

pump operation. The agreement was in all cases satisfactory, confiming the successful design of the machines. Finally,

analyzing the laboratory and numerical results, and taking

into account the observations and conclusions from all stages of the

design and construction methodology of the two models, specific proposals for

further improvements and modifications are formulated.

It is noted

that the successful completion of the physical object of 'YDROVIO' Project was

accompanied by the effective utilization of its funding, as well as the

achievement of all its outflow and evaluation Indicators.

The benefits

from the implementation of the Project for the two participants were multiple

and important. The synergy throughout the duration of the Project was very

successful, effectively utilizing the technical and research capabilities of

the LHT/NTUA and the D-P Company, and consolidating

our collaboration for further research and development of innovative products,

competitive in the global market.

Publications:

The research

and technological results of the Project were published in the following

international Scientific Journals and Conferences, presenting it to the

international scientific community.

1.

I Kassanos, V Sanoudos-Dramaliotis, J Anagnostopoulos, Numerical

modelling of fish passage and flow interaction in a hydroturbine,

Intl. Conference HYDRO 2019, Concept to Closure: Practical Steps, Porto,

Portugal, October 14-16, 2019.

2.

G Mousmoulis1, C Yiakopoulos, I Kassanos, I

Antoniadis, J Anagnostopoulos, Vibration

and acoustic emission monitoring of a centrifugal pump under cavitating

operating conditions, IAHR International Workshop on Cavitation

and Dynamic Problems in Hydraulic Machinery and Systems 9–11 October 2019,

Stuttgart, German, .ΙOP Conference Series: Earth and

Environmental Science, Volume 405, 012003, 2019.. DOI 10.1088/1755-1315/405/1/012003

3.

I Kassanos, V

Alexopoulos, J. Anagnostopoulos, Numerical analysis of the behaviour of a Deriaz versus a

Francis reversible turbine in terms of their energy efficiency and

fish-friendly characteristics, Intl. Conference HYDRO 2020, Strategies for

Future Progress,Online

event, October 26-28, 2020.

4.

G. Mousmoulis, C. Yiakopoulos, G. Aggidis, I. Antoniadis, I. Anagnostopoulos,

Application of Spectral Kurtosis on

vibration signals for the detection of cavitation in centrifugal pumps, Applied

Acoustics, 182, 108289, 2021.

5.

I Kassanos, V Alexopoulos, J Anagnostopoulos, Numerical

design methodology for reversible Deriaz turbine with

high energy performance and reduced fish impacts,

31st IAHR Symposium on Hydraulic Machinery and Systems, 6 June - 1 July 2022, Trondheim, Norway, IOP Conf. Series: Earth and Environmental Science, 1079, 012076, 2022. doi:10.1088/1755-1315/1079/1/012076

6.

Ph Koukouvinis and J

Anagnostopoulos, Simulating Fish Motion through a Diagonal Reversible Turbine, Energies,

16, 810, 2023. .https://doi.org/10.3390/en16020810.

7.

Ph

Koukouvinis and J Anagnostopoulos, State of the Art in Designing Fish-Friendly

Turbines: Concepts and Performance Indicators, Energies, 16, 2661, 2023. https://doi.org/10.3390/en16062661

8.

Ph Koukouvinis and J

Anagnostopoulos, A fast 6-DoF tracking method for submerged

bodies: application to fish passage through a turbine, ICNAAM 2022

– 20th Intl Conf. on Numerical Analysis and Applied Mathematics 19-25 September

2022, Heraklion, Crete, Greece. IOP (to

be published).

9.

I Kassanos, V

Alexopoulos J Anagnostopoulos, Design verification of a

reversible Deriaz turbine with increased efficiency

and improved fish friendly characteristics, Applied Energy Journal

(submitted).

An open Technical Workshop was also

organized, live-streamed on social media, which is available online: https://www.youtube.com/watch?v=8eOb4WLs-ww&ab_channel=DRAKOSPOLEMIS

Finally, the Company, in collaboration with

LHT/NTUA, created a specialized website exclusively for the Project, at the

address: www.hydrovio.gr, providing an interactive space where the

stakeholders can find more information and results of the Project.